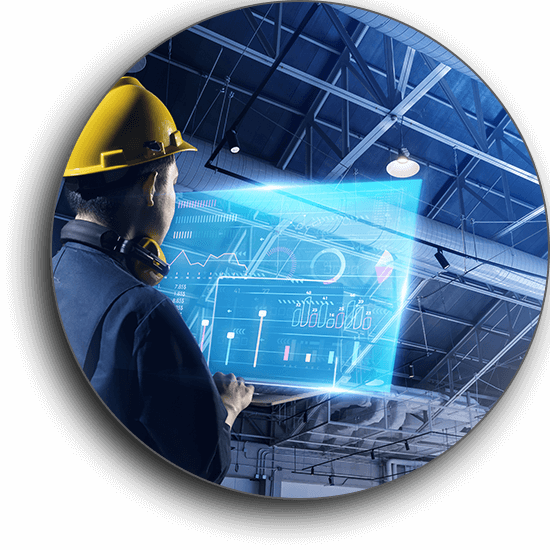

Simulation

Design and visualize highly reliable and lean processes

To simulate means to try. With real existing systems such as manufacturing systems, you can only experiment to a very limited extent for reasons of cost and time. It is even impossible with systems in the planning stage. The simulation is a way out of this problem. Simulation models can realistically represent any complex system and serve as a safe environment for experiments. The knowledge gained from the experiments can then be used for planning and operation of real systems, in order to have lean and cost-conscious processes.

Do you have further questions about simulation?

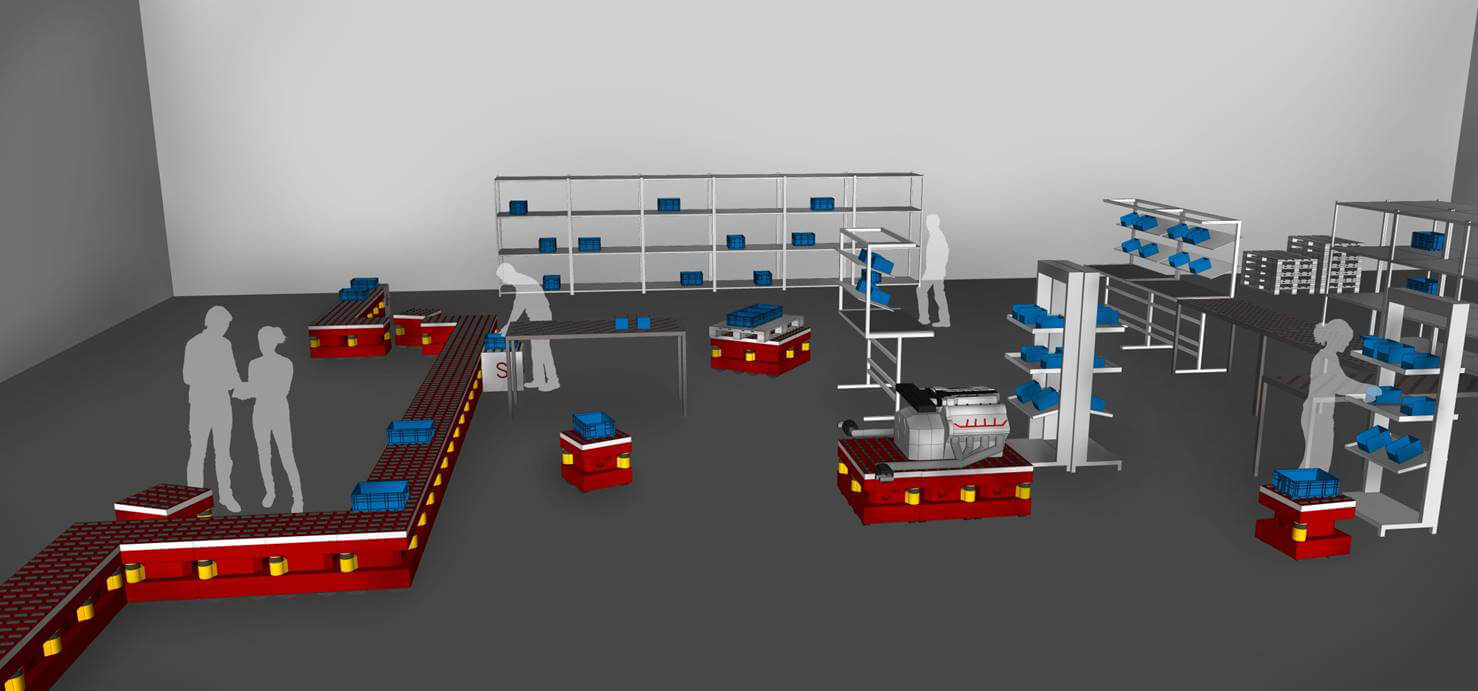

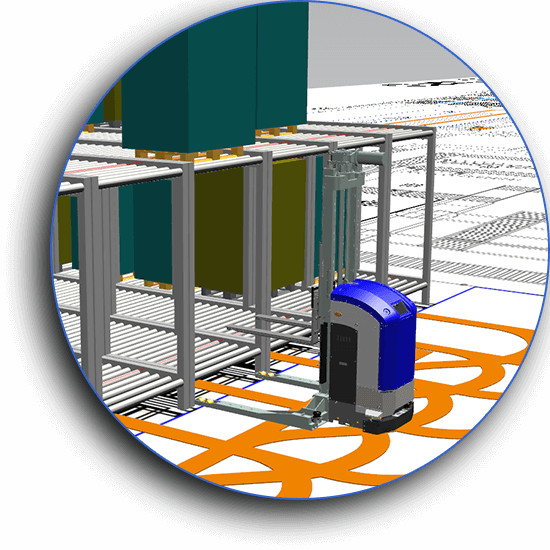

AGVs

In recent years, AGVs (Automated Guided Vehicles) have become popular in many areas of intralogistics. The advantages are increased flexibility and reduced costs, whereas the complexity of planning increases. Transport orders need to be scheduled, AGVs need to be controlled and a strategy for battery charging must be drafted. We support you in your project.

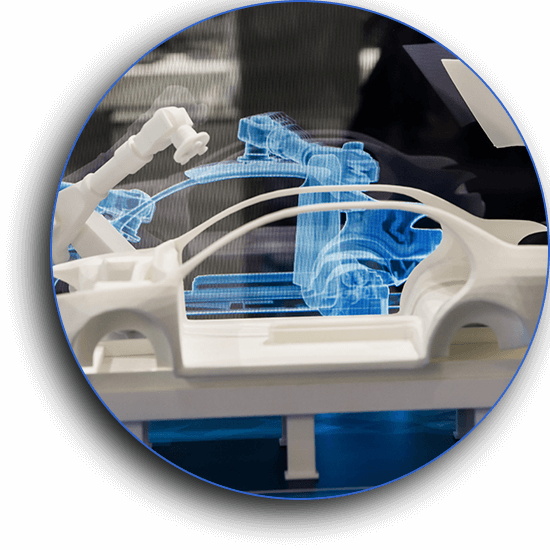

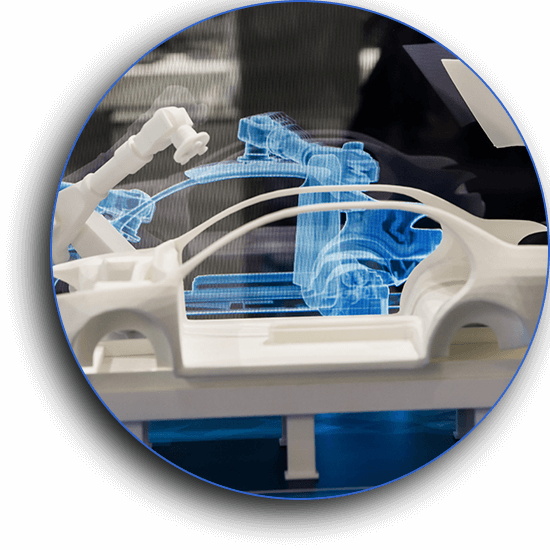

Digital twin

A digital twin is the virtual counterpart of the real production by the simulation model. The digital twin receives production data and machine statuses in real time. The entire production can be monitored by the simulation model. Optimizing the process flow in the simulation can lower the operating costs of real production.

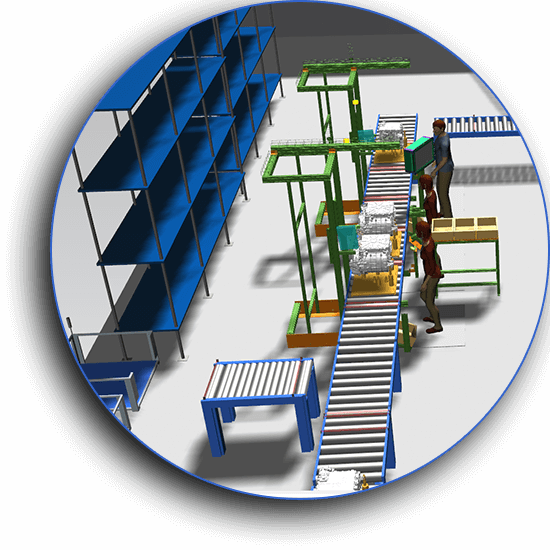

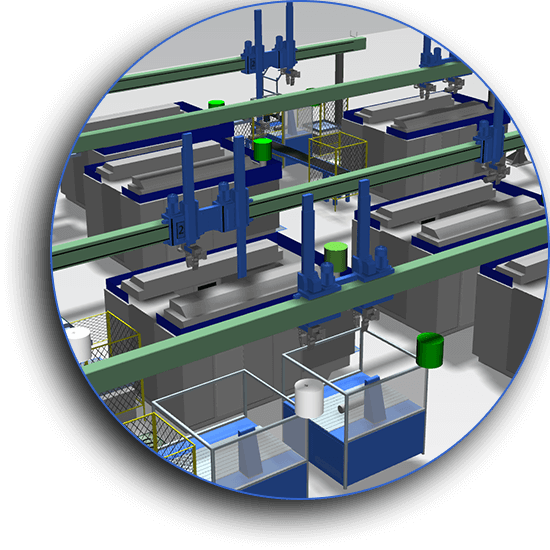

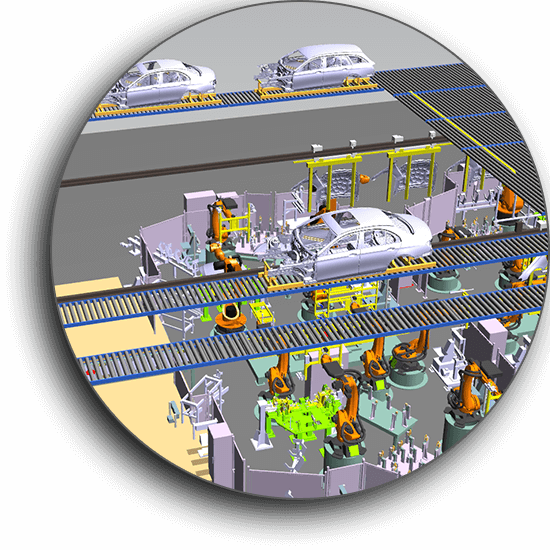

Assembly

Assembly processes are complex processes such as just-in-time provision of materials or the manpower and resource planing. The simulation supports you in the planning and the optimal design of the assembly process landscape.

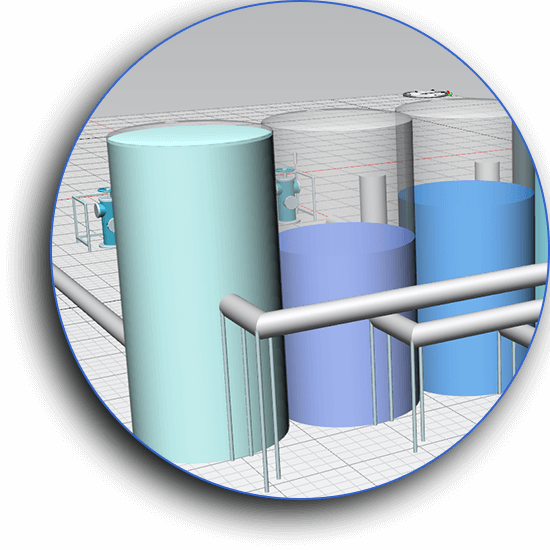

Process industry

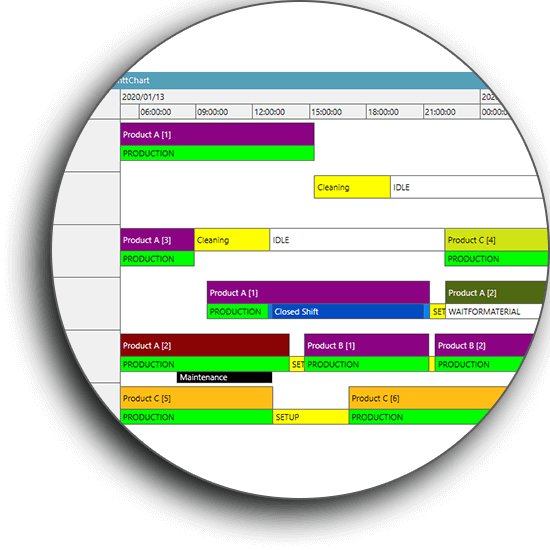

The combination of discrete and fluid processes is the core of modelling in the process industry. Complex set-up and cleaning processes are modelled in order to size the production facility or to optimize weekly schedules.

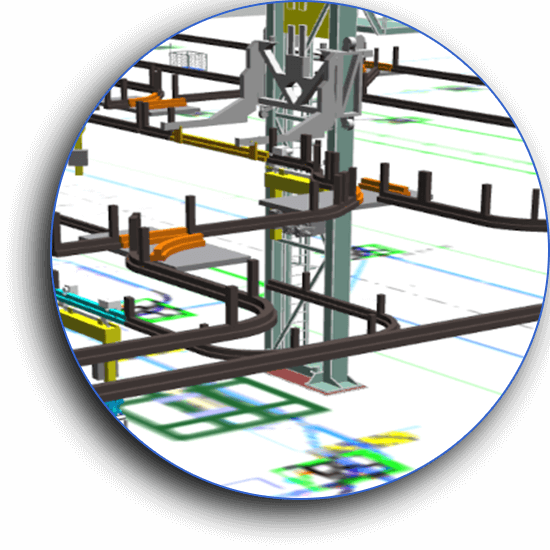

Materials handling

Conveyor technology is an important part of manufacturing processes. The simulation supports the planning, dimensioning and the final validation of control strategies.

Production

Industrial production is characterized by highly dynamic and complex systems. Simulation can display the production transparently, which allows detailed analysis. The results of this help to optimize production processes reducing inventories and throughput times.

Energy

Many companies face green challenges such as a CO2 neutral production. The simulation tool supports the tracking of energy consumption in the production system, enabling an overall optimization.

Visualization

Convince your customers of your designed processes with a 3D visualization. All process steps can be simulated in detail with powerful 3D environment of Plant Simulation. On the basis of the simple visualization of processes without interactions, a detailed simulation model can later be created to validate the performance.

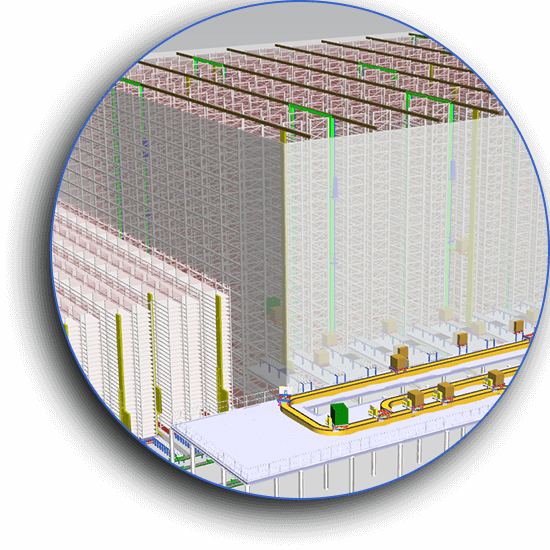

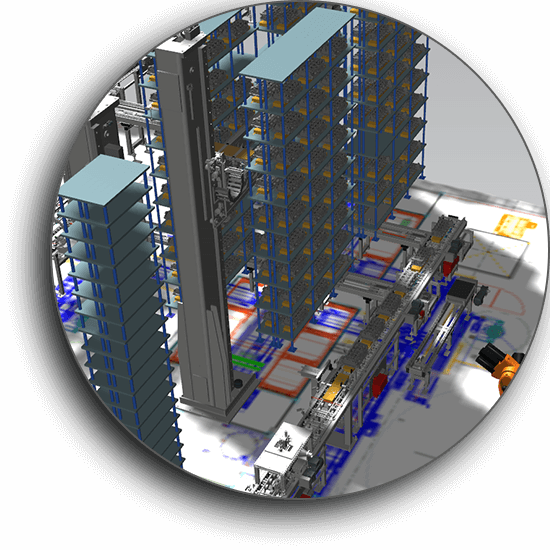

Warehouse logistics

The throughput of storage systems (such as high-bay warehouse, small parts warehouse, block storage, etc.) can be validated by a simulation including the connected intralogistics. Whether your system is based on simple transport matrices or detailed order structures, pushing or pulling strategies, we build a precise simulation model, in order to increase your planning security.

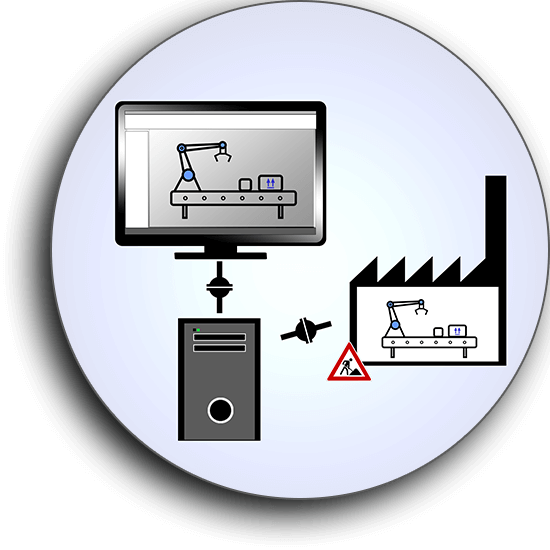

Emulation

A safe test environment for your control software

The real automation software or control is coupled with a virtual system model – simulation model (emulation).

A digital twin is developed that is used as a test environment for virtual commissioning. In comparison to the “conventional” commissioning on the construction site, a more structured and plannable approach is possible. With our experience from numerous projects, we offer solutions that are individually tailored to your application. Those solutions help to identify possible errors and weak points in the automation software at an early stage.

We also attach particular importance to the fact that our emulation models are flexibly expandable. This means that our models can be operated over the entire lifecycle of the real system. Using object orientation, our modules can be transferred to libraries that allow expansions and new models to be implemented quickly and efficiently.

Do you have further questions about emulation?

Virtual commissioning

A large number of tests can be carried out before commissioning with a simulation model. Our 3D simulation models show real systems in detail and represent or emulate mechanics, actuators and sensors. Coupling the real automation software with the simulation model, it serves as a test environment for virtual commissioning, which allows validation of the entire automation before onsite setup.

Coupling

The control software can be connected to the simulation software the same way as it is coupled with the real system, although it is still under development. The control system makes the decision while the simulation model executes movements and sends feedback to the control. We have a large number of protocols and connections available for connection. Definitely for your system as well – feel free to contact us

WMS / MFC

Warehouse management systems and material flow control are typical areas of application for virtual commissioning. In addition to the fast and economical validation of the control software prior to setup, virtual commissioning constitutes another major advantage. Errors and special situations can be tested and analysed more comprehensively than in reality. A protocol-based communication via a socket interface and TCP / IP is often used, for which any protocol and applications such as SAP EWM can be integrated.

PLC

The simulation model is linked to the process level and the actual PLC program of the real system. The simulation model processes the signals and visualizes the movements and processes. The current status of the sensors and actuators is continuously fed back to the control. The data exchange can be carried out via a variety of different interfaces. In addition to OPC / OPC UA, specific interfaces such as PLCSIM Advanced, TIA portal or SIMIT are also available.

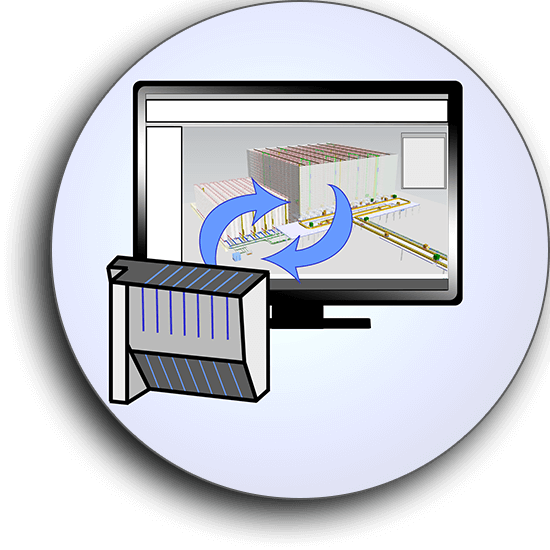

Digital Twin

Over the entire life cycle of a system, a digital twin is beneficial for planning, management and control of processes. In the early phases of the development process, the simulation model can be used as the basis of the digital twin, in order to validate concepts. In further project phases the complete system functionality can be tested with virtual commissioning. During operation the current status can be visualized, monitored and optimized. In the end, future developments can be predicted.

Visualization

Visualization increases transparency and the understanding of the system. Different system states and critical processes can be displayed in detail. This information helps to discuss and decide about future developments and solutions. The visualisation of system states is not only useful for monitoring the system, but can also be used as a training environment for employees.

Optimization

Continuously improve value-adding processes

In production and logistics there are usually many possible combinations of control parameters. Using conventional optimization methods, it is difficult to find objective optima quickly and reliably. In addition, goals such as the reduction of production time and the minimization of the use of resources are contrary.

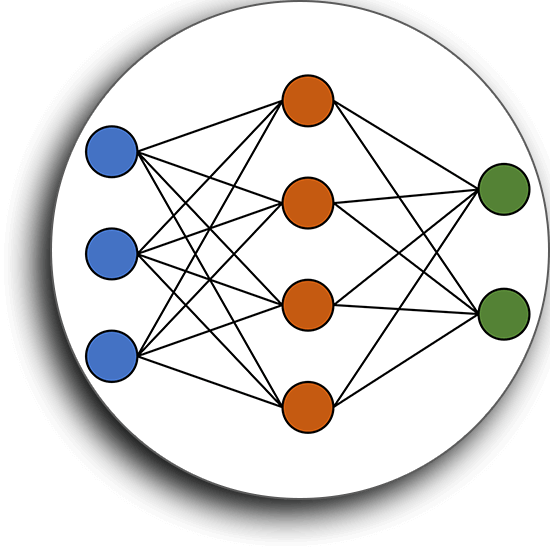

Integrating optimization in the simulation helps to understand and optimize such complex environments. By means of machine learning, neural networks and genetic algorithms, among other things, existing simulation models can be modified or newly created. These integrated models make it possible to solve any complex problem.

Do you have further questions about optimization?

Sequencing

In order to plan the production sequence, the simulation model helps to evaluate the quality of the plan. The optimal assignment to the machines and the production sequence of the orders are determined in such way, that productions interruptions as well as set-up and cleaning times are minimized. There are no limits in terms of model complexity. Therefore, production sequences can also be determined for any complex production process.

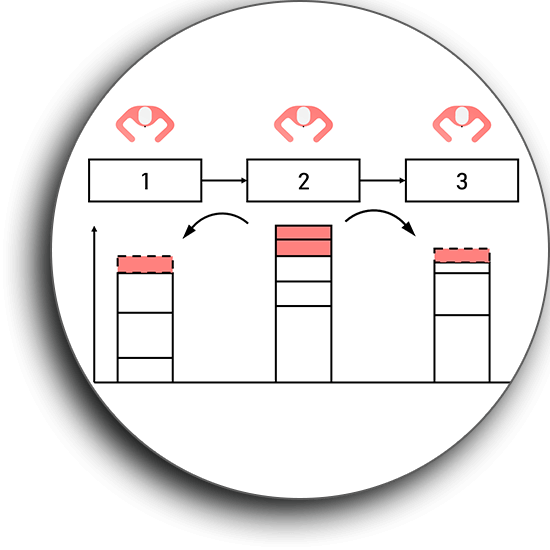

Buffer

Dimensioning the optimal buffers is a complex and time consuming problem. Since buffers consume valuable production space, the buffer should be reduced as much as possible while still ensuring the required output. We developed a process, which is specially designed for the optimization of simulation models with activated failures on stations, such as buffers

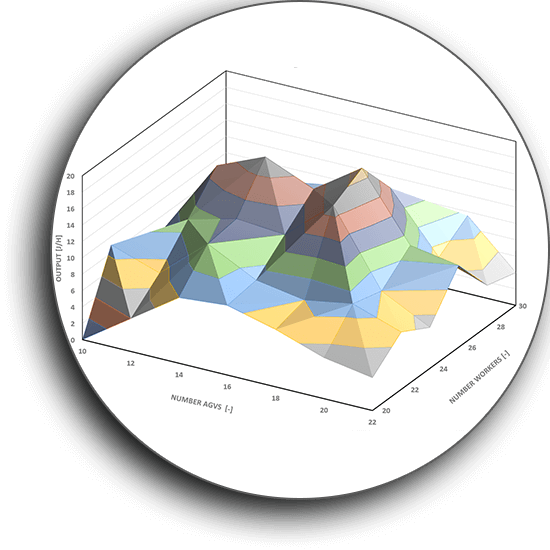

Ressources

If there are correlations between the cost effects of different ressources (such as AGVs and buffers), the entire system should be optimized considering all cost factors. We support you by developing a simulation model exactly adjusted to your requirements with an additional optimization. We use sampling- and deep-learning methods to determine further operating points and the optimal resources combination.

Line balancing

If cycle times are not matching across a line, inefficiencies arise. We develop individual methods that aim to achieve an intelligent combination of work operations. Taking into account the assembly priority graphs and constraints, the methods are adapted until a balanced utilization of the resources is achieved.

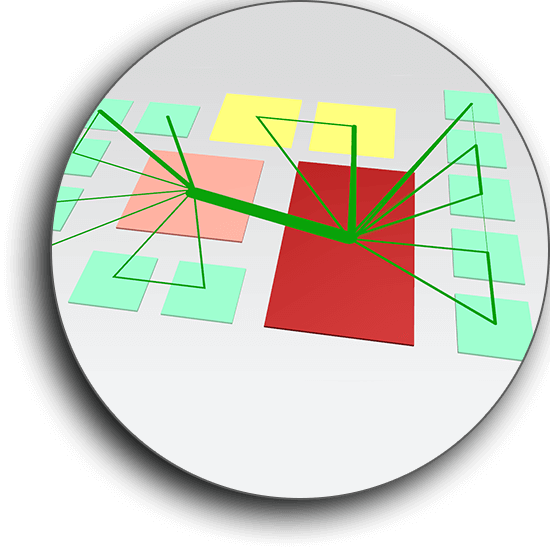

Layout planning

According to the LEAN philosophy, an accurate layout planning reduces transport times and improves the process flow. We have experience in designing generic algorithms in consideration of the conditions and using them to optimize the layout.

Methodology

We adjust evolutionary algorithms to your needs and couple them with our own developed processes. If the problems are complex, we convert simulation models using machine learning methods into mathematical functions, which can be optimized with analytical optimization processes.

Training

Understand and apply simulation

We look forward to passing on our vast experience in the simulation of different production and logistics systems to you in the form of training and coaching. In addition to standard basic training courses for Siemens Plant Simulation, we can custom individual and efficient trainings for you, based on your daily tasks and your industry.

Do you have further questions about training?

Research

Shape the future trough joint research

PPI is in constant exchange with universities and research institutions, which includes in particular, regular participation in research projects in the field of simulation and which includes holding lectureships.

Do you have further questions about reasearch?

ForBAU

2008 - 2011

Participation in the joint project ForBAU in the Bausim (construction simulation) sub-project under the leadership of the Technical University of Munich. Utilization of the material flow simulation in the construction planning in order to simulate the whole construction project virtually before starting it.

mikroKOMO

2017 - 2019

The aim of the mikroKOMO research project under the umbrella of the Hahn Schickard-Gesellschaft in Stuttgart, is the development of integrating new software tools for the development, design and operation of micro-assembly systems. PPI-Informatik has developed an extensive library for the simulation of micro-assembly processes and systems.

Atlas competence assembly – collaborative and versatile

Germany is an important industrial nation on a world scale. The Assembly plays a decisive role in the added value in the manufacture of complex industrial goods. With that in mind, the Federal Ministry of Education and Research (BMBF) launched the ideas competition “Competence in assembly – collaborative and versatile – in 2015. The project atlas “competence assembly” prepares the results in a new clear form. As part of the mikroKOMO project, Stefan Pfaff from PPI-Informatik, examined the simulation of modular micro-assembly systems against the background of changing market requirements.

Networking

- PPI is founding member of the Intralogistik Netzwerk Baden-Württemberg e.V.

- PI is part of the Industry Advisorx Concil fo the Online Master in Logistics Management at University of Stuttgart and for the Information–Logistics program at HFT Stuttgart.

About us

Your competent partner for simulation and optimization

We are a partnership founded in 1996 that carries out and supports simulation projects for a large number of customers from various industries with over twenty years of experience. Our team is composed of employees with various backgrounds such as logistics, computer science and mathematics, in order to solve our customers problems holistically.